Elevators

USE:

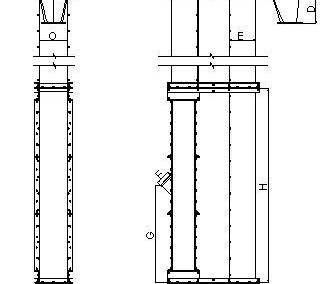

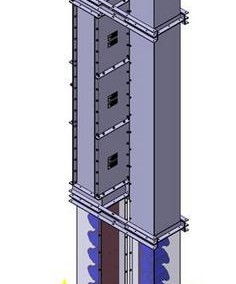

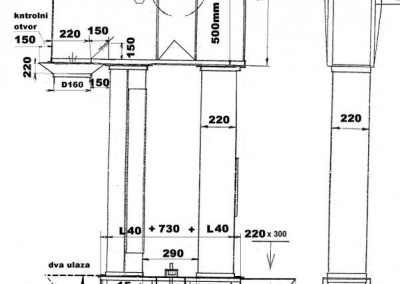

Elevators are used for vertical grain transport in silos. Parts of the elevator are: head section, boot section, pipes, belt with buckets.

HOW IT WORKS:

- Grain is brought to elevator through an opening in the boot section that can be set in front or back side of the elevator.

- Buckets grab grain and carry it up.

- Due to centrifugal force that acts on the curve of a drum, grain flies out of the bucket and moves along trajectory which represents the resultant of volume of drum speed and gravitational acceleration.

- Drum speed volume and head profile should be selected in a way that each grain falls into outlet orifice on the head of elevator.

Elevator Capacity (Q) is calculated according to the formula:

Q= Z x i x v x u x k(kg/h)

Z= number of buckets

i= volume of bucket (m3)

v= band velocity (m/sec)

u= bulk density (kg/m3)

k= coefficient of elevator loading

Engine power of the elevator (N) is calculated according to the formula:

N= (Q x H) : (367 x k) (Kw)

Q= elevator capacity (kg/s)

H= lifting height (m)

k= coefficient of efficiency of elevator.

Switches and pipelines for grain transport

USAGE AND OPERATION:

- Pipelines are used for grain gravitational transport.

- Projected diameter of a pipeline is D= 200mm.

- Wall thickness of pipeline is 2mm.

- During grain transport through pipeline, special attention needs to be brought to the angles under which pipeline is installed.

- If the angle is more vertical, grain fall buffers are necessary.

- Grain that falls vertically heats the pipeline and shortens its service life.

- Soy transport through pipeline uses up pipe walls the most. In this case pipelines need to be replaced more frequently.

- Switches, routers serve to direct grain in a certain direction.

- Switchers are designed for manual switching.

- Switchers can be controlled by cables from ground.